If you do any DIY or other woodworking projects, you need to buy lumber. Most people can accomplish this at the big box stores like Home Depot, Lowes, and others. If all you need is construction lumber, they have it. If you want to do something with a hardwood, you can usually get something like Red Oak or Poplar. Most of these stores do not carry any other hardwoods. The lumber will be in the S4S format. S4S means “surfaced on four sides”. That means top, bottom, and both edges. You don’t need to do any cleanup of the lumber, it is ready to use.

If you are a woodworker like me, you may buy your hardwood from a real lumberyard. The one I use sells probably 40 different hardwoods. Some of the wood is domestic hardwood like Maple, Oak, Ash, Walnut and Cherry. These woods are grown in America. They are less expensive than exotic hardwoods grown and imported from other countries. Domestic hardwood, generally, costs less than exotic hardwood.

Let’s take this a step further. Many woodworkers buy their lumber in S2S classification. S2S means “surfaced on two sides” which is usually top and bottom. In other words, the wood has been surfaced top and bottom so it has a uniform thickness. The edges are rough cut and uneven. The typical woodworker buys this type of hardwood, then finishes the wood preparation in his or her shop by putting clean edges on the boards and making the wood “square”. The wood you work with has to have accurate dimensions all the way around, or you cannot build anything with it.

I buy my hardwood in S2S condition. Then I bring it home and finish milling it. Typically, this involves using a tool called a Jointer to put one clean, 90° edge on a board. This is what a Jointer looks like:

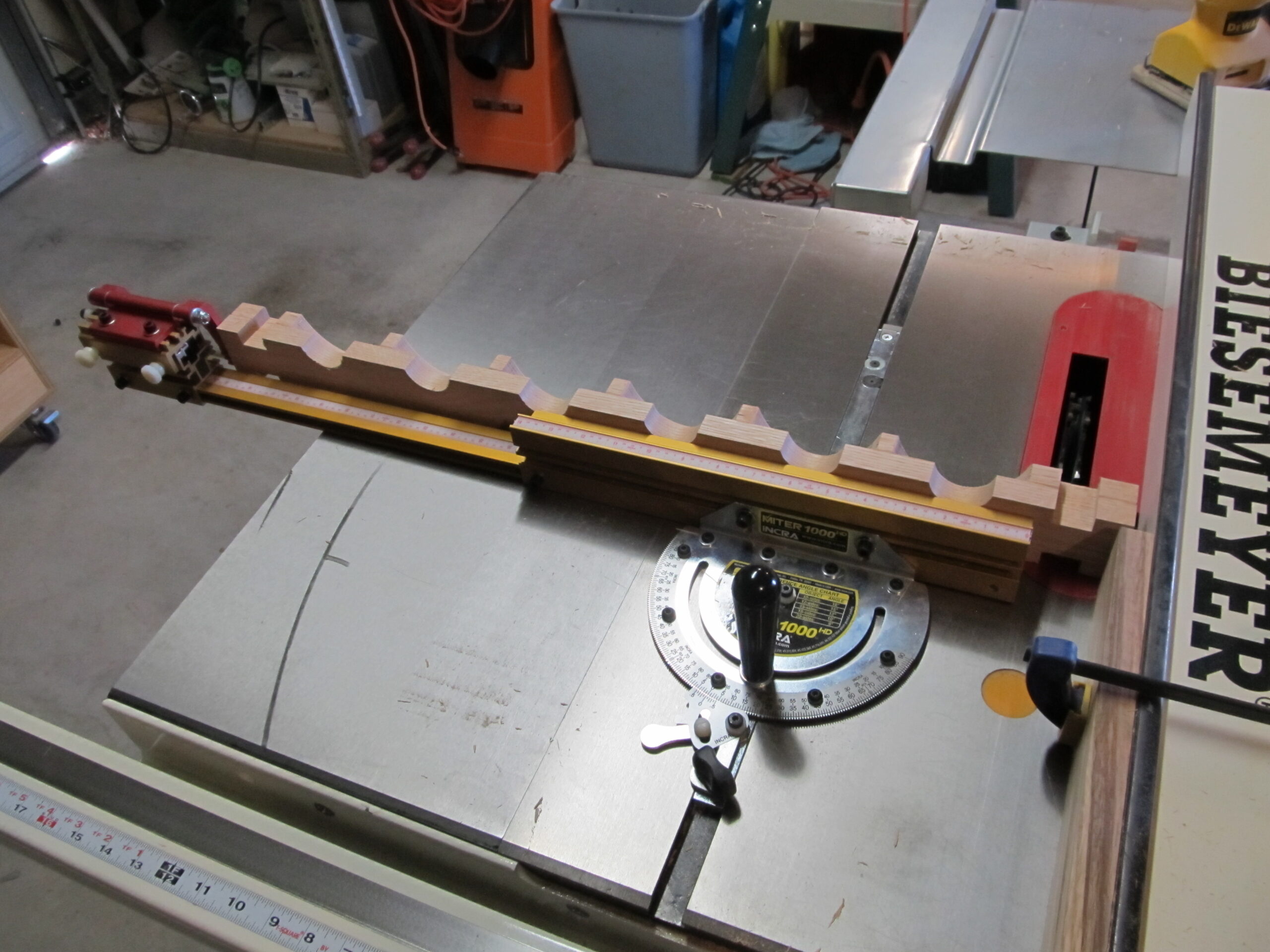

You run one edge of the board across the little table until it is smooth. Then you take that smooth edge and put it up against the fence on a Table Saw. When you run the board through the table saw blade, both edges will be equal distance apart throughout the length of the board. You now have a S4S dimensioned board. Here is what a table saw looks like:

Why buy lumber in S2S format? Price! The company you buy it from does not have to do as much milling to get it ready for sale, so they charge less. It makes buying lumber for a project a little more difficult because the wood is not perfectly dimensioned. But, seasoned woodworkers know to buy 20% more wood than you think you need for a project, which gives you some leeway when preparing your pieces for assembly.

For my Cherry wood table project, I will be buying S2S lumber at my local wood store. I enjoy milling it into workable pieces, and it saves me money. Maybe I will show you some photos of this process when I do it.

Doug